Ben Lipscomb

Performing a duct traverse is a fundamental skill that air balancers need to master. It’s also a key skill for HVAC technicians who want to measure and improve system performance for their customers. With the different instruments available for performing a traverse, it can be confusing to know when to use which instrument.

If you’re just starting out with duct traverses, you might be struggling to decide which instrument to buy. This in-depth article covers instrument selection for duct traverses and provides you with clear recommendations on what to buy first, and what to use when.

The Pitot Tube

The classic tool for performing a traverse is the Pitot-static tube (or simply Pitot tube for short) with an inclined or u-tube fluid-filled manometer. The Pitot tube was invented in 1732 by French hydraulic engineer Henri Pitot, who originally developed the concept to measure waterflow in the Seine river.

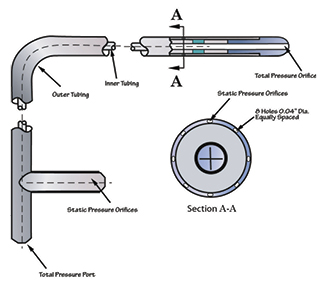

Figure 1: A modern Pitot-static tube design for airflow measurements. An inner tube with an orifice that faces into the flow measures total pressure. Orifices arranged around an outer tube are oriented perpendicular to flow to measure static pressure. Total Pressure minus Static Pressure equals Velocity Pressure, which can be converted to air velocity.

Henri’s original Pitot tube had some design issues that limited its practical use and accuracy. These and other limitations persisted for more than 120 years, relegating the Pitot tube to ‘little more than a scientific toy’ until another French engineer, Henry Darcy, systematically improved the design of the Pitot tube.

Because of the extent of those improvements, some have proposed calling the device a ‘Pitot-Darcy’ tube. Both Pitot and Darcy used this instrument for measuring liquid flows, but today it is most often used to measure airflow.

Today, we enjoy further advancements in the design of the Pitot tube as well as the development of accurate digital manometers which make them among the most accurate tools to measure airflow inside ducts. They are also convenient and robust enough to use in the field.

The Pitot tube does have its limitations.

ASHRAE 111 states that a Pitot-static tube traverse is not practical below a 600 fpm (feet per minute) velocity, and manufacturers of digital manometers intended for the purpose generally don’t recommend using Pitot tubes below 1,000 fpm.

With a typical high-end ‘field-grade’ digital manometer, accuracy at 600 fpm is about +/-10% and accuracy at 1,000 fpm is +/-4%. This puts the Pitot-tube out of range for most residential and light commercial airflow measurement applications, where velocities are almost always below 1,000 fpm, and are often below 600 fpm

An alternative to the standard bent-tube Pitot is a ‘straight Pitot’ or ‘airfoil’ type probe, which doesn’t have the 90-degree bend and is easier to insert into ducts through pressure ports.

These types of probes also have pressure orifices oriented directly into and directly away from the airflow. This amplifies the pressure signal, so you can use them with slightly lower airflows than a standard Pitot tube.

Be aware that the same effect limits the upper velocity ranges that can be measured depending on your manometer selection. Specific equations supplied by the manufacturer must be used with straight Pitot or airfoil probes.

Figure 2: Straight Pitot and Standard Pitot Tubes.

Digital Manometers for Pitot Tube Measurements

When you select a digital manometer for Pitot tube measurements, it is extremely important to pay attention to the instrument’s accuracy and range specifications.

Digital manometers are often specified with accuracy as a percent of the full scale of the instrument. Because of this, an instrument with a range of 0 to 1 in. w.c. (inches of water column) will be far more accurate for typical HVAC airflows than an instrument with the same accuracy and a range of 0 to 20 in. w.c. A manometer with a 0 to 1 in. w.c. range will work well up to about 4,000 fpm. These are often marketed as ‘micromanometers.’

That said, there are some instruments on the market that have a wider range (e.g. -15 to 15 in. w.c.) and specify accuracy as a percentage of the reading with an additional absolute accuracy term to account for the fact that accuracy is lower at lower flow rates. Some of these instruments have accuracy throughout the measurement range that’s comparable to a quality 0 to 1 in. w.c. manometer.

Figure 3: A digital manometer connected with flexible tubing to a Pitot tube. This is a good choice for air velocities over 1,000 fpm. Generally these velocities are found in high-volume commercial systems.

Sometimes manometers specifically intended or marketed for air velocity measurement specify percent accuracy at a specific velocity.

Remember, the velocity used is often much higher than typical HVAC duct velocities, and accuracy deteriorates as velocities decrease.

The Thermal ‘Hot-Wire? Anemometer

A ‘Hot-Wire’ or Thermal Anemometer measures electrical resistance through a heated element. The resistance changes depending on airflow over the element.

Thermal anemometers have come a long way in terms of their accuracy, measurement range, and robustness for use in the field.

Figure 4: Two different thermal anemometers

For example, ASHRAE 111 cites accuracies of +/-10% and maximum ranges of 600 fpm. However, modern instruments claim accuracy as low as +/-3% with a measurement range up to 6,000 fpm.

With these specifications, it makes them the clear choice if most of your measurements will be in velocities less than 1,000 fpm.

If you regularly test systems with velocities above 1,000 fpm, a thermal anemometer can still be a good choice for convenience. Most thermal anemometers also measure temperature, and some higher-end models also incorporate relative humidity and barometric pressure sensors.

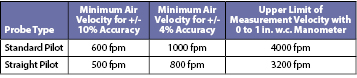

Table 1: Minimum velocities for 10% and 4% accuracy for Standard vs. Straight Pitot tubes with a typical digital manometer (+/-0.5% of full scale; 0 to 1 in.-w.c. range)

These sensors turn the instrument into a multi-function tool, but more importantly they allow the instrument to automatically compensate for air density and display your measurement in either actual or standard CFM. That’s something you must do manually with a Pitot tube measurement.

One aspect to be aware of when using a thermal anemometer is that it won’t indicate flow direction. With a Pitot tube you can rotate the probe to find where the reading is highest, and the position of the probe indicates the direction of the flow. This can help you identify areas with swirl, eddies, or reverse flow that you will want to avoid when performing a traverse.

A straight Pitot or airfoil probe can also measure flow in both directions, so you’ll know if your measuring a flow profile that isn’t developed enough for an accurate measurement. Thermal anemometers can’t be used for diagnosing your measurements like this.

Other issues to be aware of with thermal anemometers include:

- High sensitivity to wind, turbulence, changes in building pressure, and other airflow disturbances

- Possible reduced accuracy at low or high temperature and humidity extremes

- Probes can be fragile, and may become fouled when used in dirty environments

- The heated probe can ignite combustible gases. Do not use in flammable environments.

The Right Tool for YOUR Job

Obviously, you can put a lot of thought into selecting instruments for doing a duct traverse. The good news is, the selection can be really simple if you don’t care to dig in.

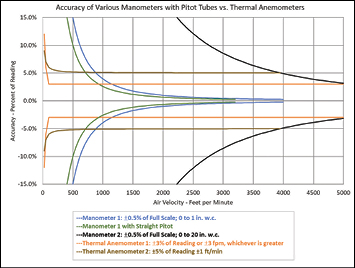

Figure 5: Accuracy of several manometers with Pitot tube and Thermal Anemometer options. Thermal anemometers are generally best below about 1,200 fpm. Above 1,200 fpm a Pitot tube with an appropriate digital manometer is more accurate, but thermal anemometers have some attractive features and are good to between 4,000 and 6,000 fpm.

Here are a few simple rules to follow if you’re thinking about buying your first instrument for duct traverses or adding to your stable:

- If you’ll be working on residential or light commercial work exclusively, you’ll probably want a thermal anemometer. You’ll also want a manometer for checking static pressures, but you won’t need the high accuracy or the limited range that sometimes come with that accuracy for your purposes.

- If you work on larger commercial equipment but don’t require the absolute highest accuracy, and you only measure airflow in ducts with velocities under 6,000 fpm, a thermal anemometer is probably still a great choice for versatility and convenience.

- If you’re a professional balancer working on a wide variety of systems, you’ll probably want to have both a Pitot tube setup and a thermal anemometer. This will allow you to tailor your tool to your specific measurement application, always selecting the instrument that will provide the best outcome.

You’ll probably also want several Pitot probe lengths in addition to some Straight Pitot probes to further increase your options and versatility.

As is always the case with field measurement, it’s good practice to double check your measurements if you suspect an issue with accuracy. Always remember to use your knowledge of the entire system to evaluate the plausibility of each measurement.

Ask yourself ‘given what I know about this system, does this measurement make sense??

By taking this approach and applying the information presented in this article, you can always be sure you’re using the right tool for your job.

Ben Lipscomb is a registered Professional Engineer with over 14 years of experience in the HVAC industry including laboratory and field research, Design/Build contracting, and utility energy efficiency program design.

He is National Comfort Institute’s engineering manager, and may be contacted at benl@ncihvac.com.

I recently did a traverse using my EBT 3710 and a pitot tube. Then I did the exact same traverse using my TSI Alnor hot wire anemometer and got quite different results. So less than 1200 fpm hwa. Greater than 1200 fpm pitot tube. Got it. Thanks for the article. This explains a lot.

Thank you for taking the time to put this article together. However I’d like to know more about how these reported results were established. What procedures were used, what was the conditions under which the tests were conducted. Or are these results from a study and can you provide that information.

Good morning Kyle and thank you for your post. We have forwarded your question to the author and will respond both here on the site and directly to you via email when he responds. –TheEditor

Thanks for the question, Kyle. The accuracy reported on the chart for various manometers and anemometers are actually just the manufacturer’s reported accuracy values converted to common terms to allow for easy comparison. The various instrument manufacturers each express accuracy in different ways (e.g. percent of reading vs. percent of full scale vs. absolute accuracy, fpm vs. in.w.g., etc). The specific math for converting to common terms varies based on how the manufacturer expresses accuracy, but it all leverages the basic equation: velocity feet per minute = 4005 x square root (velocity pressure in. w.g.).

POSTED ON BEHALF OF KYLE NELSON:

Thank you for responding, I was curious to know if you did your own testing and if so under what conditions. I asked about the testing methods as there have been a few studies that have suggested that the hot wire is more reliable and accurate in field conditions. However having said that it ultimately depends on the user and field conditions, at the end of the day that will have the largest impact on the accuracy of the readings.

I appreciate the fact you didn’t pick one instrument definitively, there are still a lot of professionals out there suggesting that the pitot tube is still the only way to accurately measure anything. We have had to break out the slope gauge now and then to prove to someone that the accuracy of the hot wire is just as reliable, without all the additional calculations.

Regards,

Kyle Nelson

Senior HVAC Balancing Technician